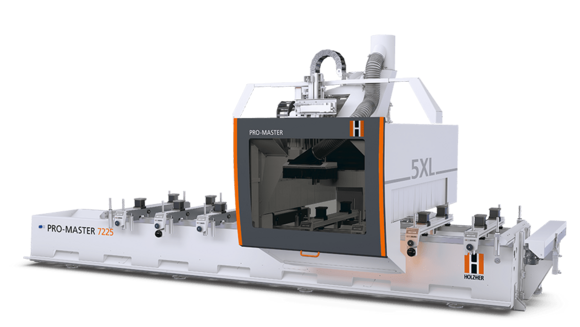

Our vertical horizontal and 5 axis machining centers offer a wide range of platforms that combine stability power and accuracy with our proven technologies.

Vertical machining center definition.

The former is attached to a high speed air turbine spindle mounted on c table.

Vertical machining occurs on a vertical machining center vmc which employs a spindle with a vertical orientation.

The vertical machine is preferred where three axis work is done on a single face as in mold and die work.

Vertical machining centers also referred to as vertical milling machines are preferred for flat parts that must have through holes.

Vertical machining also known as milling relies on rotary cutters to remove metal from a workpiece.

The integration of milling into turning environments and vice versa began with live tooling for lathes and the occasional use of mills for turning operations.

The machining center is designed based on the concept of friction free servo structures.

Tongtai vtx drilling tapping machines provide high precision.

This led to a new class of machine tools multitasking machines.

These categories are the bedmill and the turret mill.

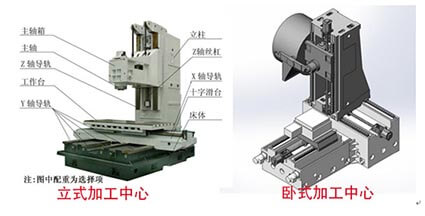

The orientation of the spindle is the most defining characteristic of a cnc machining center types include vertical machining centers vmcs horizontal machining centers hmcs and 5 axis machining centers.

The term machining center describes a cnc milling and drilling machine that includes an automatic tool changer and a table that clamps the workpiece in place.

The vertical machining centers have two subcategories.

As illustrated in the figure the machining center has two type cutting methods according to the employed tool viz rotational tool or non rotational tool.

Milling centers are generally classified as vertical machining centers vmcs or horizontal machining centers hmcs.

Definition of vertical machining center.

Vertical machining center vmc process description.

The machines may be described by the axis in which they are set up to work such as horizontal or vertical.

With rapid traverse speeds ranging to 2 362 ipm 60 m min in all axes and acceleration of 1 2 g tongtai s.

A machining center with a spindle that is perpendicular to the ground floor vertical machining centres are creating the parts and die molds that matter with precision accuracy repeatability and surface finishes that virtually eliminate bench work.

Vertical machining occurs on a vertical machining center vmc which employs a spindle with a vertical orientation.

Different machining centers have the ability to work in different axes or planes.

Designed for maximum productivity our automation packages allow for total flexibility and lights out operation.

Okuma s genos m660 v vertical machining center combines a large work table a compact machine footprint and a cat 40 big plus spindle for machining large complex parts.